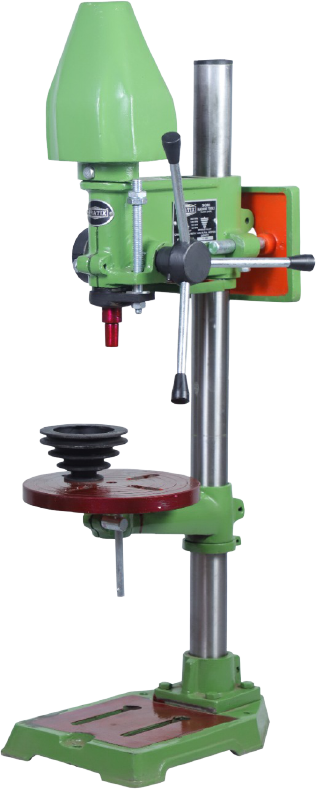

A pillar drill, also known as a drill press, is a stationary machine used to drill precise holes in various materials. Here's an overview of the process:

Setup: Securely mount the material to be drilled on the drill press table using clamps or a vise.

Selecting Drill Bit: Choose the appropriate drill bit for the material and hole size.

Installing Drill Bit: Insert the drill bit into the chuck and tighten it securely.

Setting Speed: Adjust the drill speed according to the material being drilled (higher speeds for softer materials, lower speeds for harder materials).

Drilling: Lower the drill bit onto the material using the handle or lever, ensuring it starts at a slow speed to prevent damage.

Cooling: Apply cutting fluid or lubricant if necessary to cool the drill bit and reduce friction.

Completion: Once the hole is drilled to the desired depth, release the handle and turn off the machine.

Base: Supports the entire machine and provides stability.

Column: Vertical structure that houses the motor and drive mechanism.

Table: Surface where the material is placed, usually adjustable in height.

Drill Head: Contains the motor and spindle, which holds and rotates the drill bit.

Spindle Speed Control: Allows adjustment of the drill speed.

Metalworking: Drilling holes in metal parts for assembly or further machining.

Woodworking: Creating precise holes in wooden components for joinery or decorative purposes.

Machining: Producing accurate holes in various materials for industrial applications.

| Tags: | #PILLAR DRILL MACHINE MANUFACTURERS IN RAJKOT, #PILLAR DRILL MACHINE MANUFACTURERS RAJKOT, #PILLAR DRILL MACHINE MANUFACTURER IN RAJKOT, #PILLAR DRILL MACHINE IN RAJKOT |